rockwell hardness test method as defined in astm e-18|rockwell astm e18 : warehouse Scope. 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell . Monster High: Bem Vindos a Monster High (Monster High: W.

{plog:ftitle_list}

WEBProcure 122 Wandinha PNGs com fundos transparentes para download isento de royalties.

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .

Scope. 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell .

rockwell hardness testing standard

rockwell hardness testing methods

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. .The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell . 1 These test methods are under the jurisdiction of ASTM Committee E28 on Mechanical Testing and are the direct responsibility of Subcommittee E28.06 on Indentation .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test.

The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell .ASTM E18 is a standard test method used to determine the Rockwell hardness of metallic materials. Rockwell hardness is a measure of a material’s resistance to indentation, similar to .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. The Rockwell test is generally easier to perform and more accurate than other hardness methods.The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. The customer should get a copy of these standards and .

ASTM E18 is the industry standard for Rockwell hardness testing of metallic materials. This specification includes both theory and standard practice statements. For those companies Nadcap accredited in heat treat where the .ASTM E 18-07 Standard Test Methods for Rockwell Hardness of Metallic Materials is the active and current standard by which Rockwell Hardness . The Rockwell Hardness Test is considered to be more accurate and easier to .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials. Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials E0018-02 ASTM|E0018-02|en-US Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic . .00: . The Rockwell hardness test is a non-destructive testing method performed by comparing depth of indentations. The test is defined in ASTM E-18 and ISO 6508-1. The hardness test is named after the inventor of the Rockwell hardness tester machine. Significance and Use 4.1 The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical . Standard Test Methods for Rockwell Hardness of Metallic Materials E0018-24 ASTM|E0018 .

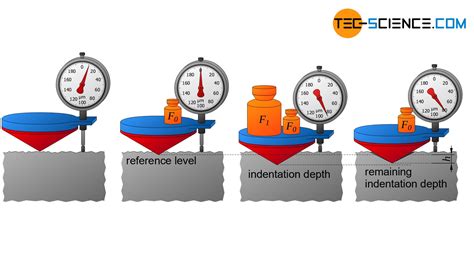

5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficialtreatment and quality of manufactured parts. Rockwell testing is covered by ASTM test method E 18. While all indentation hardness tests generally serve the same purpose, each one has definite advantages that make the test more applicable to certain types of materials and part geometries. Brinell is used primarily on forgings and cast iron. Rockwell hardness test methods are standardized in ASTM E18-24: . The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by . Buy ASTM E 18 : 2022 Standard Test Methods for Rockwell Hardness of Metallic Materials from Intertek Inform. Customer Support: +1 416-401-8730. . Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials ASTM B 692 : 2018 : R2023: Standard Specification for 75 % Silver-25 % Graphite Sliding Contact Material .

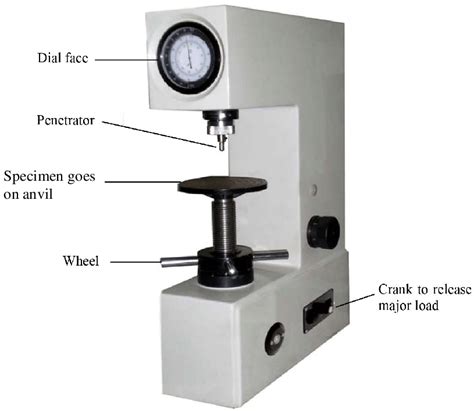

rockwell hardness testing machine

Buy ASTM E 18 : 2022 Standard Test Methods for Rockwell Hardness of Metallic Materials from Intertek Inform. Customer Support: +44 (0) . Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials ASTM B 692 : 2018 : R2023: Standard Specification for 75 % Silver-25 % Graphite Sliding Contact Material .ASTM International standards E 10, Test Method for Brinell Hardness of Metallic Materials, and E 18, Test Methods for Rockwell Hardness of Metallic Materials, have both recently undergone extensive revisions.Both standards are under the jurisdiction of Subcommittee E28.06 on Indentation Hardness Testing, which is part of ASTM International Committee E28 on . Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials A description is not available for this item. View Less . This document references: ASTM A1038 - Standard Test Method for Portable Hardness Testing by the Ultrasonic Contact Impedance Method. Published by ASTM on October 1 , 2019. This test .3.1.5 Rockwell superficial hardness test—same as the Rockwell hardness test except that smaller preliminary and total test forces are used with a shorter depth scale. 3.1.6 Rockwell hardness number—a number derived from the net increase in the depth of indentation as the force on an indenter

The shore hardness test uses pin-shaped indenters, whereas a Barcol indenter is used in Barcol hardness testing. In this test, ASTM D785-08 (2008) and ASTM E 18-11 (2011) methods can be applied for measuring the hardness. For Rockwell hardness test in silk composites samples, a total of 10 indentation points can be measured on the samples . Significance and Use 4.1 The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical . Standard Test Methods for Rockwell Hardness of Metallic Materials E0018-15 ASTM|E0018 .

Rockwell Test Method, as defined in ASTM E-18, is the most commonly used hardness test method. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods. The Rockwell test method is used on all metals, except in condition where the test metal structure or surface conditions would introduce .

Revision of E18-22 Standard Test Methods for Rockwell Hardness of Metallic Materials. . ASTM Standard C33, 2003, "Specification for Concrete Aggregates," ASTM International, West Conshohocken, PA, 2003, DOI: 10.1520/C0033-03, www.astm.org. Referencing Standards (multiple revisions in same year): .In metallurgy hardness is defined as the ability of a material to resist plastic deformation. . according to the specifications of ASTM E-18. This test measures the difference in depth caused by two different forces, using a dial gauge. . test or Rockwell hardness test. Both methods measure the resistance of the plastic toward indentation .Last previous edition E 18 – 98. 2 In this test method, the term Rockwell refers to an internationally recognized type of indentation hardness test as defined in Section 3, and not to the hardness testing equipment of a particular manufacturer. 3 Annual Book .1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for Rockwell hardness testing (Part B) and the calibration of .

Please contact us for a detailed quote for your astm e18 testing needs. Cost incurred to carry out different astm e18 testing methodology depends on the type of raw material; number of samples, coupons, or specimens; test conditions, turn around time etc. Costs of some ASTM testing methods start from 0 and the final value depends upon the factors listed .1.5 Units— At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons (N) and length in millimeters (mm).5.1.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98

Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials. Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials E0018-00 ASTM|E0018-00|en-US Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic . .00: .

rockwell hardness test formula

Rockwell hardness test sesuai ISO 6508 / ASTM E18. . Super Rockwell methods (sesuai ASTM E18) Ikhtisar berikut menunjukkan semua metode Super Rockwell yang distandarisasi menurut ASTM E18, dan penerapannya. Pra-beban uji untuk semua metode adalah 3 kg. . ASTM E-18; DIN 51917; To the product Kontak. Contact. ZwickRoell. August-Nagel-Straße 11.

rockwell hardness test blocks

rockwell astm e18

e18 rockwell hardness

Resultado da 21 de fev. de 2024 · Written By Corey Sharp on February 21, 2024. The Pennsylvania Gaming Control Board (PGCB) approved the online casino license for Roxor Gaming on Wednesday. The online casino manufacturing company had been operating in the Keystone State since December after .

rockwell hardness test method as defined in astm e-18|rockwell astm e18